Industrialisation consists in making a product manufacturable on the basis of the project's target cost, the requested technical specifications, the quantity and quality requirements and the available technology.

Industrialisation corresponds to a company's need to optimise production with a view to reducing costs and processing times and improving productivity and quality.

PROCEDI is able to optimise product and process characteristics and design the necessary equipment, defining the variable and fixed production costs together with the customer.

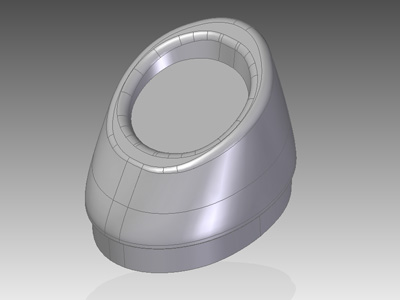

The industrialisation process starts with the design. The designer, making reference to the product specifications, does the analyses and calculations needed for the initial dimensioning of the part. Also in this phase, the initial functional geometry and appearance are modelled in CAD.

The next stage is the prototyping, where, with the use of rapid-prototyping technology, an initial physical sample of the component is made. This step is of great use in the design process in that it allows a functional and clearance assessment to be made on the generated component.

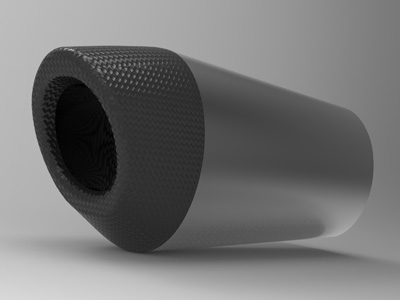

For a better understanding of the end result, the prototyping can be accompanied by a rendering CAD, which gives a very realistic impression of what the final item will look like.

If all these steps give positive results, a pre-series can be set up to define the equipment, processes and machining operations required for the actual production.

|

The industrialisation process starts with the design. The designer, making reference to the product specifications, does the analyses and calculations needed for the initial dimensioning of the part. Also in this phase, the initial functional geometry and appearance are modelled in CAD. |

|

The next stage is the prototyping, where, with the use of rapid-prototyping technology, an initial physical sample of the component is made. This step is of great use in the design process in that it allows a functional and clearance assessment to be made on the generated component. |

|

For a better understanding of the end result, the prototyping can be accompanied by a rendering CAD, which gives a very realistic impression of what the final item will look like. |

|

If all these steps give positive results, a pre-series can be set up to define the equipment, processes and machining operations required for the actual production. |